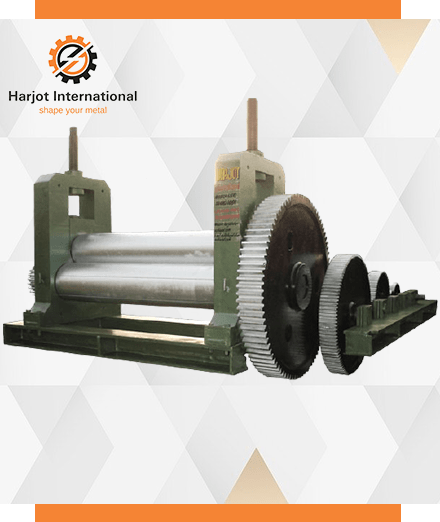

Achieving flatness is crucial when working with sheet metal components and blanks. Straightening machines are designed to correct any curvature in sheet metal parts and blanks that originate from coils. These machines not only save time that would otherwise be spent on manual straightening but also minimize raw material wastage.

Read this article to learn about straightening machines and key considerations for choosing the right one for your specific needs.

Understanding What a Straightening Machine Is?

A straightening machine is a specialized industrial tool designed to correct the deformations or irregularities present in various types of materials, such as metal, plastic, or even certain textiles. It operates on the principle of applying controlled pressure and force to bring these materials back to their original, straightened state.

What’s the Purpose of a Stratighning Machine Exactly?

The primary purpose of a straightening machine is to ensure that materials meet specific quality standards, which is crucial for their subsequent processing or use in various industries. By eliminating bends, kinks, or twists, these machines enhance the material’s structural integrity and improve its functionality.

How is this Straightening Machine Used in Various Industries?

In industries like manufacturing, straightening machines play a vital role in the production process. For instance, in metalworking, they are used to refine raw materials like steel, aluminum, or copper before they undergo further fabrication. This is especially important in sectors like automotive, aerospace, and construction, where precise and high-quality materials are essential for safety and performance.

In addition to metalworking, straightening machines find applications in other sectors as well. For instance, in the textile industry, they are used to straighten and align threads or fibers before they’re woven into fabrics. In the plastics industry, these machines help correct any irregularities in plastic sheets or extruded profiles, ensuring consistent quality in the final products.

Moreover, straightening machines have also found their place in specialized fields like paper production, where they’re employed to flatten and align paper rolls, enhancing printability and overall quality.

Consider the Below Factors While Choosing a Straightening Machine

Choosing the right straightening machine is crucial for businesses or individuals looking to achieve precise and efficient results. Here are some important factors that you can consider before buying this machine:

Capacity and Size:

Determine the size and volume of materials you’ll be straightening. Ensure the machine’s capacity aligns with your production needs. Avoid overloading or underutilizing the equipment.

Material Compatibility:

Different straightening machines are designed for specific materials. Consider the type, thickness, and hardness of the materials you’ll be working with. Ensure the machine is compatible with your intended applications.

Straightening Mechanism:

There are various types of straightening mechanisms, including roller, press, and hydraulic. Each has its strengths and limitations. Research and choose the mechanism that best suits your requirements.

Accuracy and Precision:

The level of precision needed for your applications is important. Some industries require extremely high levels of accuracy, while others may allow for slight variations. Make sure the machine’s specifications match your precision requirements.

Adjustability and Customization:

Look for machines that offer adjustable settings. This allows you to fine-tune the straightening process to meet specific needs. Customizability is especially important for dealing with diverse materials.

Ease of Use and Maintenance:

A user-friendly interface and clear operational instructions can save time and reduce the learning curve. Additionally, consider the maintenance factors your machine needs as well as the availability of spare parts.

Brand Reputation and Reviews:

Research the manufacturer’s reputation and read customer reviews. This can give you insights into the quality, reliability, and customer support of the product.

Budget and ROI:

Make your exact budget depending on your company’s financial capacity. Consider the machine’s long-term return on investment (ROI) and possible savings or higher productivity.

Warranty and Support:

Check the warranty offered by the manufacturer. Additionally, inquire about available support options, such as technical assistance and spare parts availability.

Tips and Practices for Keeping Straightening Machines in Optimal Condition!

Proper maintenance and care of straightening machines is crucial to ensure they operate efficiently and have a long lifespan. Here are some tips and best practices to help you keep your straightening machine in optimal condition:

Regular Cleaning: Begin by cleaning the machine regularly. Use a soft cloth to remove dust, debris, and any accumulated residue. Pay special attention to the rollers, guides, and any moving parts.

Lubricate your Machine: Lubricate the moving parts as recommended by the manufacturer. Lubricating your machine helps reduce friction and wear on critical components. Be sure to use the appropriate type of lubricant specified in the machine’s manual.

Inspect Rollers and Guides: Check the condition of the rollers and guides frequently. Look for signs of wear, chipping, or misalignment. To avoid additional damage, replace any broken components as soon as possible.

Alignment Check: Periodically verify that the machine is aligned correctly. Misalignment can lead to uneven straightening and put unnecessary stress on the device. Adjustments should be made according to the guidelines of top Straightening Machine Manufacturers in India.

Monitor Tension and Pressure Settings: Keep an eye on the tension and pressure settings used for straightening. Using incorrect settings can cause excessive strain on the machine and lead to premature wear.

Regular Inspections: Conduct routine inspections for signs of wear, loose bolts, or any abnormal noises during operation.

Professional Service and Calibration: Schedule regular professional service and calibration according to the manufacturer’s recommendations. This ensures that the machine is operating at its peak performance.

Address Issues Promptly: If any problems arise during operation, address them promptly. Delaying repairs can lead to further damage and potentially more costly repairs.

Conclusion

In this blog, you get an understanding of straightening machines and how you can choose the right one. By following the above tips, you can ensure that your straightening machine remains in optimal condition.

Harjot International has established itself as a renowned name in the field of industrial machinery in India, mainly known for its exceptional straightening machines. With a track record of delivering top-notch equipment, they have earned the position of one of the best Straightening Machine Suppliers in India.