The food and beverage manufacturing industry is going through a transformation, due to the integration of technology and automation. This shift not changes how things are done but also brings improvements in efficiency, quality and safety. It benefits both producers and consumers alike. Let’s explore some of the advancements in technology and automation such as twins, meticulous tracking systems, robotics and automation as well as artificial intelligence and machine learning integration.

The world of food and beverage manufacturing is experiencing a change as it embraces the age. Recent times have witnessed a shift towards technology and automation leading to the emergence of factories and sparking discussions about digital transformation. The potential lies in achieving efficiency levels, improved quality control measures and enhanced safety standards within the industry – all of which will have outcomes for consumers, manufacturers and the communities they serve.

By exploring concepts like transformation and examining the landscape of manufacturing, the goal is to provide valuable insights into how Smart Factories are poised to revolutionize the food and beverage industry.

Digital Transformation in the Food and Beverage Manufacturing Industry

One of the drivers behind the digital transformation in the food and beverage manufacturing industry is the pressing need for increased efficiency and productivity.

To improve efficiency, reduce costs and enhance Overall Equipment Effectiveness (OEE) as well as production outputs, food and beverage manufacturers are constantly seeking ways to optimize their processes. The integration of technologies such as Artificial Intelligence (AI) machine learning and robotics offers a solution to achieve these goals. For example, by leveraging AI and machine learning algorithms, manufacturers can quickly analyze volumes of data with accuracy, enabling real time quality decision making. Additionally, robotics plays a role by handling repetitive tasks that would otherwise require human effort. This allows human workers to focus their energy on innovative assignments.

Moreover, there is an increasing attention on sustainability which puts pressure on enterprises to reevaluate their practices and explore environmentally friendly approaches.

In this context, technology emerges as a force. By combining creativity with capabilities, businesses have an opportunity to embrace sustainability.

To give an example, AI and machine learning can be used to optimize supply chains reducing waste and increasing efficiency. The shift towards factories is not about technology; it also has cultural and environmental implications.

Smart Manufacturing Trends in Food and Beverage Industry

The food and beverage industry is currently experiencing changes in manufacturing. These include

- Tracking the journey of products from farm to table ensuring transparency.

- Tracing products from their source in the field to their delivery point.

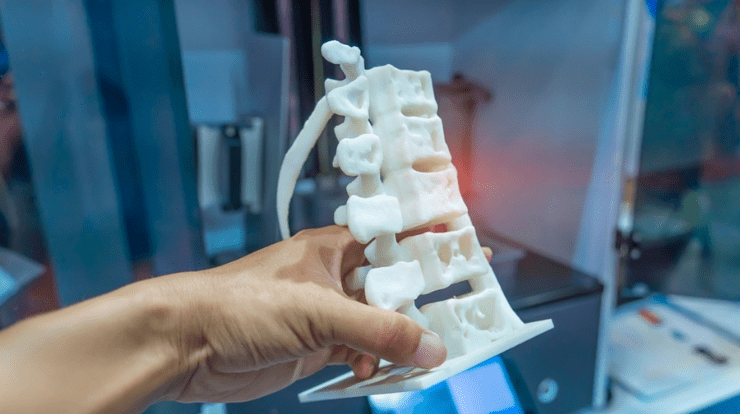

- Implementing factories that use robots for efficient processes.

- Using laser guided vehicles along with IoT for connectivity.

While these trends offer potential, it is important for food and beverage manufacturers to approach them cautiously.

To fully leverage the advantages of manufacturing, companies need to integrate this technology into their core business systems.

Here are three important factors to consider when embracing manufacturing in the food and beverage industry:

- Mobile Barcoding for Smooth Connectivity: Embrace the use of mobile barcoding to ensure inventory updates are in time. This enables traceability paths that instantly update an ERP system. By integrating this technology, companies can quickly adjust production based on demand and shortages maintaining up to date records and enhancing flexibility.

- Prioritize Traceability: Traceability is a benefit of manufacturing especially for food producers. It allows organizations to respond promptly and accurately during product recalls or safety concerns. With mobile inventory tracking, all products can be meticulously recorded, making it easier to identify contaminated inventory. Without integration, recalls may involve batches, negatively impacting productivity and profitability. Traceability also improves field mobility by providing offline solutions that keep workers connected in remote areas ensuring no transactions are lost.

- Embrace Operational Agility: The current business landscape requires adaptability for success. A strong supply chain strategy combined with inventory solutions and food and beverage software provides real time insights, throughout the warehouse and delivery process.

Manufacturers have the ability to quickly adapt their production processes in response to changes in demand, unexpected shortages and unforeseen interruptions. For example, a company specializing in consumer goods packaging successfully managed an increase in production during the pandemic by utilizing supply chain software and food and beverage software. This allowed them to promptly reassign tasks and meet the rising demand.

Why is the Smart Factory Manufacturing Operations Management (MOM) system considered a smart solution for the food and beverage manufacturing industry?

Think of the Smart Factory MOM system as an intelligent assistant specifically designed for food and beverage manufacturing. It’s like having a trusted companion that ensures everything runs seamlessly.

This system oversees every stage of food production until it reaches its to-be consumed state. It diligently monitors each step ensuring that everything proceeds smoothly.

In case any issue arises, such as machinery breakdown, the MOM system quickly alerts someone so that they can address it before it escalates into a problem. It’s akin to having a superhero who detects trouble and calls for assistance!

However, the capabilities of the MOM system extend beyond problem solving; it also excels at predicting issues. It can identify when machines may require maintenance even before they malfunction or break down.

You know what’s really cool? The Smart Factory MOM has this ability to anticipate when there will be a demand, for food and prepare accordingly. But here’s the thing it’s not about machines. Smart Factory also values the input of its workers.

They can freely share their ideas and this fantastic MOM system helps foster collaboration among everyone. In the world of food and drink where precision is the key, the Smart Factory MOM acts like a sidekick. It keeps an eye over operations, resolves any issues that arise, and even seems to predict what will happen next. It’s like having a friend who ensures that everything tastes delicious and runs smoothly according to the schedule.