In Dubai’s dynamic gaming industry, companies often grapple with the challenge of balancing cost-effectiveness with the demand for innovative and customizable gaming peripherals. Traditional manufacturing methods may entail high setup costs and large minimum order quantities, making them less feasible for small-scale production runs.

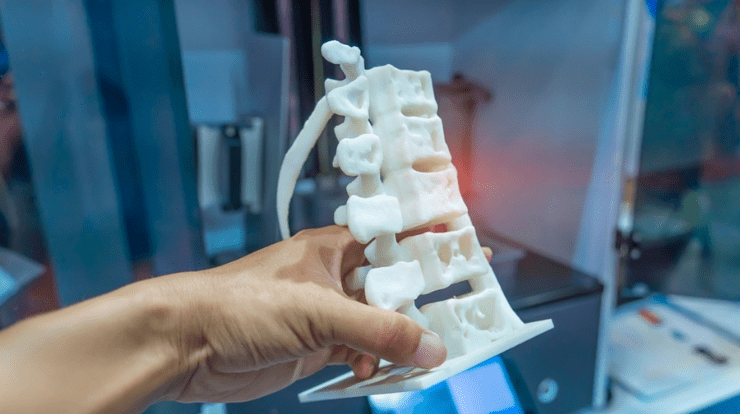

However, the advent of 3D printing technology has revolutionized the landscape, offering a promising alternative for small-scale production of gaming peripherals. In this comprehensive analysis, we explore the factors that determine the cost-effectiveness of 3D printing for small-scale production in Dubai’s gaming industry and assess its viability as a manufacturing solution.

Understanding the Cost Dynamics of 3D Printing

Before delving into the cost-effectiveness of 3D printing Dubai for small-scale production of gaming peripherals, it’s essential to understand the cost dynamics of this innovative manufacturing process.

Unlike traditional subtractive manufacturing methods, which involve cutting away material from a solid block, 3D printing, also known as additive manufacturing, builds objects layer by layer from digital designs.

This layer-by-layer approach offers several advantages in terms of material efficiency, reduced waste, and design freedom. However, the cost-effectiveness of 3D printing depends on a variety of factors, including material costs, machine utilization, labor expenses, post-processing requirements, and overhead costs.

Material Costs and Selection

One of the key cost drivers in 3D printing is the cost of materials used to produce the desired gaming peripherals. While traditional manufacturing methods often rely on standardized materials purchased in bulk, 3D printing offers a wider range of material options, including thermoplastics, resins, metals, and composites.

The cost of these materials varies depending on factors such as material type, quality, and supplier. In Dubai, where access to specialized materials may be limited compared to other regions, material costs can impact the overall cost-effectiveness of 3D printing for small-scale production.

However, advancements in material science and the emergence of local suppliers are expanding material options and driving down costs, making 3D printing increasingly competitive for small-scale production runs.

Machine Utilization and Throughput

Another critical factor influencing the cost-effectiveness of 3D printing is machine utilization and throughput. 3D printers come in various sizes, configurations, and capabilities, ranging from desktop printers suitable for prototyping to industrial-scale machines capable of high-volume production. Maximizing machine utilization and throughput is essential for optimizing production efficiency and minimizing per-unit manufacturing costs.

For small-scale production runs, selecting the right 3D printing technology and optimizing print parameters can help balance speed, quality, and cost. Additionally, leveraging batch processing, nesting parts, and scheduling print jobs strategically can further enhance efficiency and reduce manufacturing costs.

Labor Expenses and Post-Processing Requirements

While 3D printing offers automation and efficiency advantages over traditional manufacturing methods, labor expenses and post-processing requirements remain significant considerations for small-scale production in Dubai’s gaming industry. While 3D printing itself is largely automated, tasks such as file preparation, machine setup, part removal, and post-processing (e.g., cleaning, support removal, surface finishing) require human intervention and expertise.

Labor costs associated with these activities can impact the overall cost-effectiveness of 3D printing, particularly for small-batch production runs. However, advancements in software automation, workflow optimization, and post-processing techniques are reducing labor requirements and streamlining production processes, making 3D printing increasingly competitive for small-scale manufacturing applications.

Overhead Costs and Infrastructure Investment

In addition to material costs, machine utilization, and labor expenses, overhead costs and infrastructure investment play a crucial role in determining the cost-effectiveness of 3D printing for small-scale production in Dubai’s gaming industry. Overhead costs encompass expenses such as facility rent, utilities, maintenance, and administrative overhead.

Infrastructure investment includes the cost of purchasing and maintaining 3D printers, ancillary equipment (e.g., post-processing tools, inspection devices), and software licenses. While these upfront costs can be significant, particularly for companies transitioning from traditional manufacturing methods, they can be amortized over time and offset by the long-term cost savings and operational efficiencies afforded by 3D printing.

Market Demand and Competitive Positioning

Ultimately, the cost-effectiveness of 3D printing for small-scale production of gaming peripherals in Dubai depends on market demand, competitive positioning, and the strategic objectives of the company.

While 3D printing offers advantages in terms of flexibility, customization, and speed to market, it may not always be the most cost-effective solution for high-volume production runs or commoditized products.

However, for niche markets, limited-edition releases, and customizable offerings, 3D printing can provide a competitive edge by enabling companies to offer unique, tailored experiences that resonate with consumers. By aligning production strategies with market demand and leveraging the inherent strengths of 3D printing, companies can unlock new opportunities for growth and differentiation in Dubai’s gaming industry.

Conclusion

In conclusion, while there are various factors to consider, 3D printing holds significant promise as a cost-effective solution for small-scale production of gaming peripherals in Dubai’s dynamic gaming industry.

By carefully assessing material costs, optimizing machine utilization, streamlining labor expenses, and strategically investing in infrastructure, companies can harness the transformative potential of 3D printing to unlock new opportunities for innovation, customization, and market differentiation.

While challenges remain, advancements in technology, materials, and process optimization are driving down costs and expanding the feasibility of 3D printing for small-scale production, paving the way for a more agile, responsive, and competitive gaming industry in Dubai.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.