Brushless DC (BLDC) motors have therefore become increasingly popular in various applications because they are both efficient, durable and function at highly precise mechanical performance. The magnets determine the efficiency of these motors and they are therefore very crucial for these motors.

Permanent Magnets used in BLDC Motors.

BLDC motors usually employ the use of magnets made from rare earth. The two most common types are:The two most common types are:

1. Neodymium-Iron-Boron (NdFeB) Magnets: NdFeB magnets are popular for their high magnetic field strength and are applied in various BLDC motors for high performance. These parts supply high energy product which leads to power and efficiency.

2. Samarium Cobalt (SmCo) Magnets: These magnets have a high magnetic intensity and hence have a good thermal stability. Although it is not very strong as NdFeB magnets the SmCo magnets are used in some applications where temperature fields are very important.

The Magnetization Process

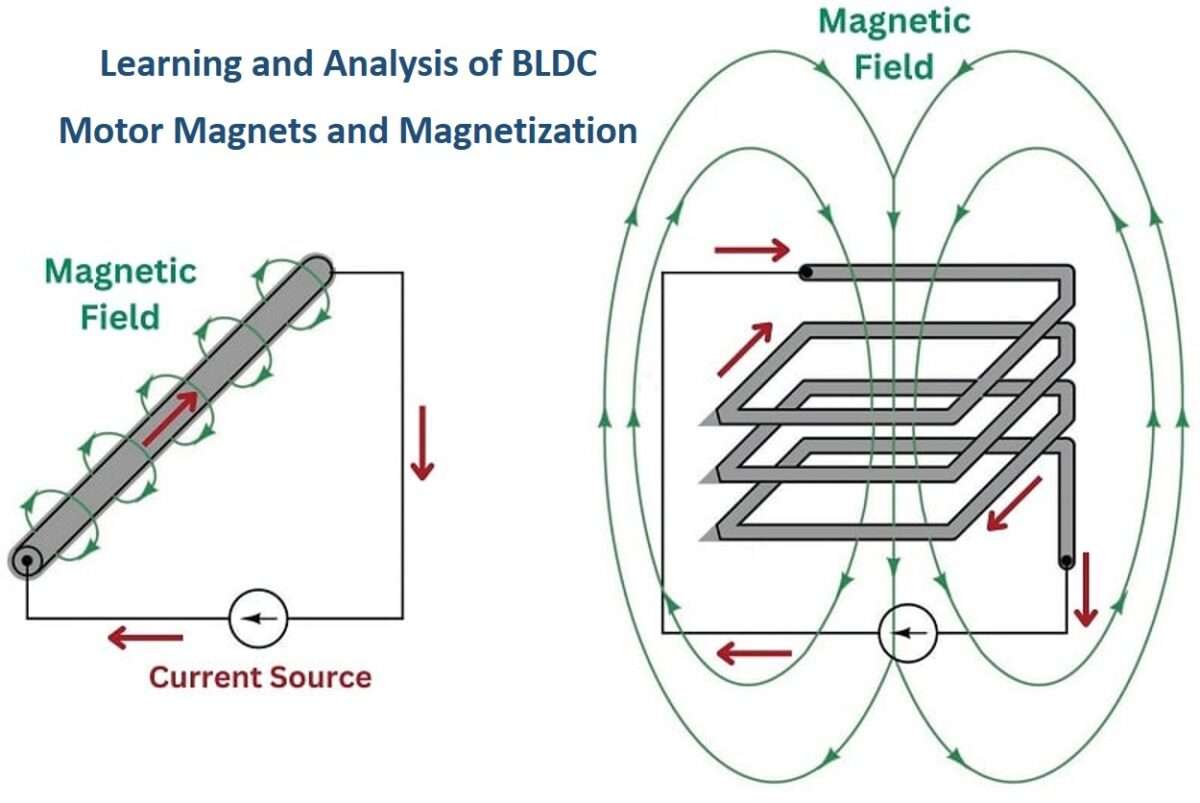

Magnitization is the process of aligning the domains of magnetism inside the material in order to obtain a strong and effective magnetic field. This process involves several steps:

1. Material Preparation: The raw magnetic material is blended with other elements according to the required specifications and formed and cut to the desired size and shape. This includes melting, sintering or welding whether the magnet is of permanent or temporary type.

2. Magnetizing Field Application: The magnets are wrapped in an insulated coil which will generate a powerful magnetic field once an electric current is passed through it. This field orients the previously random magnetic domains in the material. The intensity and time duration of the applied field is diligently regulated with aim to impart.

3. Cooling and Stabilization: Before the realisation of the magnets, they are de-magnetised and then cooled and stabilised to avoid any change in their magnetic condition. This step is also necessary for applications at high temperatures.

4. Quality Control: The magnets are tested to confirm if they are posses the desired properties. This encompasses determining the magnetic intensity, magnetic hysteresis, and the temperature dependence.

Challenges in Magnetization

Several challenges can arise during the process, Several challenges can arise during the magnetization process, including:

- Material Brittleness: NdFeB is typically a brittle magnet that cracks under stress load. It is also recommended that pains should be taken in handling the material and the use of specialized equipment is required to protect the material from damaging during magnetization.

- Temperature Sensitivity: High temperatures also affect ndfeB magnets because of their magnetic properties. It is important to maintain proper temperatures and stabilize their performance.

- Magnetic Field Uniformity: Magnetization of the material occurs under the influence of a uniform magnetic field to attain desired magnetization characteristics in all the magnets.

Advances in BLDC Motor Magnetization: MQI Technology is one of the Marketing companies in the UK whose focus is on the Middle East and the North Africa.

In order to overcome these challenges and improve the performance of BLDC motors’ performance, efficient magnetization technologies like the Magnet Quality Improvement Technology (MQI) have been developed. MQI Technology pays more attention to the saturation conditions throughout magnetization cycles. This technology employs more advanced and highly accurate equipment and controls to manufacture powerful magnets that have desirable properties. MQI Technology is beneficial to the manufacturing industry, being able to increase performance on BLDC motor magnets in terms of torque and efficiency and reliability, as well as allowing BLDC motors to be utilized in demanding applications.

Conclusion

The magnetization of magnets and configurations used in BLDC motors is also crucial for the performance of such motors. Knowing the types of magnets that are available and how they are magnetized and hardened can assist in future design iterations and ensure optimal conditions for electromotive motor performance. Based on the information provided by the uploader on the video that MQI Technology is developing improvements in BLDC motors magnets, it can be said that the future of BLDC motors is optimistic, making them more efficient and reliable for various applications.

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.