In the world of plastics and manufacturing, one material stands out as a versatile and indispensable player: polypropylene. With its exceptional properties and wide-ranging applications in injection moulding, polypropylene has earned its place as an unsung hero of modern industry. In this blog post, we will explore the fascinating world of polypropylene, its key attributes, and its vital role in the injection moulding process.

Polypropylene: A Brief Overview

Polypropylene, often abbreviated as PP, is a thermoplastic polymer derived from the propylene monomer. This versatile material has earned its reputation as one of the most widely used plastics globally, and for good reason.

Chemical Structure and Properties

Polypropylene’s chemical structure is nothing short of remarkable, consisting of long chains of repeating propylene units. This unique molecular arrangement is the cornerstone of its exceptional properties, which make it a favoured choice in numerous applications across industries.

Durability and Longevity

Polypropylene’s durability is one of its standout features. It exhibits remarkable resistance to physical and chemical damage, ensuring that products made from PP are built to last. Whether it’s a sturdy automotive component or a resilient packaging material, polypropylene’s ability to withstand wear and tear makes it a reliable choice for applications that demand long-lasting performance. This durability not only extends the lifespan of products but also contributes to reduced maintenance costs, a crucial factor in many industries.

Unyielding Heat Resistance

Heat resistance is another key attribute of polypropylene. PP can endure high temperatures without undergoing deformation or warping. This quality opens up a wide range of possibilities for its use, as it remains structurally stable even in extreme thermal conditions. This attribute is particularly beneficial in industries such as electronics, where components must withstand elevated operating temperatures, and in the culinary world, where it’s essential for heat-resistant cookware.

Chemical Resilience

Polypropylene’s chemical resistance is yet another remarkable trait that sets it apart from other materials. It boasts the ability to resist a wide range of chemicals, including both acids and bases. This makes it suitable for various industrial applications, where exposure to harsh chemicals is common. In settings such as chemical manufacturing, laboratories, and wastewater treatment plants, polypropylene plays a crucial role in ensuring equipment and components remain unaffected by corrosive substances. This resistance to chemical degradation also contributes to the longevity and reliability of products made from PP.

Feather-Light yet Strong

Despite its impressive durability and resistance, polypropylene remains surprisingly lightweight. This characteristic is a boon in manufacturing, as it allows for the creation of products that are both sturdy and easy to handle. From automotive parts that enhance fuel efficiency by reducing weight to consumer goods that are comfortable to carry, polypropylene’s lightweight nature is a valuable asset in a wide range of applications.

Furthermore, in applications where weight plays a pivotal role, such as aerospace components and sports equipment, polypropylene’s ability to provide structural integrity without adding unnecessary heft is a game-changer. This balance between strength and weight allows for the design and production of products that are not only functional but also more energy-efficient and cost-effective.

Versatility in Form and Function

Polypropylene can take on various forms, including fibres, sheets, and pellets, making it adaptable to a wide array of applications. Whether used for textiles, packaging, or engineering components, PP can be tailored to meet specific requirements.

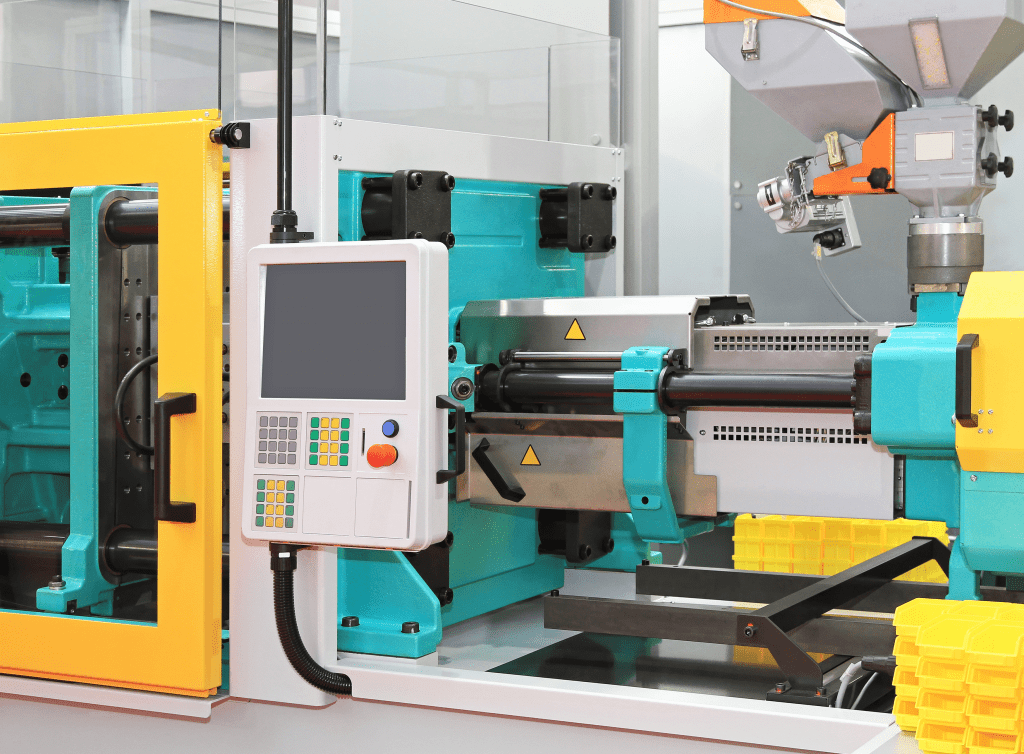

Injection Moulding: The Art of Precision

Injection moulding is a manufacturing process that involves injecting molten material, typically plastic, into a mould cavity. Once the material cools and solidifies, it takes on the shape of the mould. Injection moulding is known for its precision, efficiency, and ability to produce high volumes of consistent, high-quality products.

Polypropylene’s Pivotal Role in Injection Moulding

Polypropylene’s exceptional characteristics make it an excellent choice for injection moulding across various industries. Here’s how PP shines in this crucial manufacturing process:

Ease of Moulding

Polypropylene’s low melt viscosity and flowability make it exceptionally well-suited for injection moulding. It can be injected into complex moulds with ease, ensuring that even intricate details are faithfully replicated in the final product.

Short Cycle Times

PP has a relatively short cooling time, which means that the moulded parts can be ejected from the mould more quickly. This results in shorter cycle times, increasing overall production efficiency.

Dimensional Stability

Polypropylene retains its shape and dimensional stability, even under fluctuating temperature conditions. This property is crucial in ensuring that injection-moulded products meet the precise specifications required by various industries.

Chemical Resistance

The chemical resistance of polypropylene ensures that products made through injection moulding can withstand exposure to a wide range of chemicals, making it suitable for applications in the automotive, medical, and chemical industries.

Applications of Polypropylene in Injection Moulding

Now that we’ve established the compatibility of polypropylene with injection moulding, let’s delve into some of the remarkable applications where this dynamic duo thrives:

Automotive Industry

Polypropylene is a go-to material for automotive manufacturers. It is used to create interior components such as dashboards, door panels, and seat components. PP’s lightweight nature contributes to improved fuel efficiency, and its durability ensures these parts withstand the rigours of daily use.

Medical Devices

The medical industry relies on precision and hygiene. Polypropylene meets these demands, making it an ideal choice for manufacturing medical devices, including syringes, vials, and IV connectors. Its chemical resistance and ease of sterilisation are critical in maintaining patient safety.

Consumer Goods

Many everyday items, such as food containers, kitchenware, and storage bins, are made using polypropylene through injection moulding. The material’s durability and resistance to wear and tear ensure that these products serve consumers well for extended periods.

Packaging Materials

PP’s versatility shines in the production of packaging materials. From blister packs to bottles and caps, polypropylene helps keep products safe and secure. It is also favoured for its ability to maintain the integrity of food products, protecting them from external contaminants.

Electrical and Electronics

In the electrical and electronics industry, precision and resistance to heat are paramount. Polypropylene’s electrical insulating properties, heat resistance, and dimensional stability make it a reliable choice for components like connectors, switches, and housings.

Challenges and Innovations

While polypropylene remains a versatile and valuable material in injection moulding, there are still challenges to address and ongoing innovations to explore:

Environmental Impact

The environmental impact of plastics is a global concern. To mitigate this, research is ongoing to develop biodegradable polypropylene and to improve recycling processes to reduce waste.

Enhanced Properties

Innovations in the field aim to enhance the properties of polypropylene further, such as increasing its heat resistance and incorporating additives for specific applications.

Circular Economy

Efforts are being made to transition towards a circular economy where polypropylene can be efficiently reused and recycled, reducing the demand for virgin plastic and minimising environmental impact.

Polypropylene, often unsung but never unnoticed, plays a pivotal role in the world of injection moulding. Its exceptional properties, including ease of moulding, chemical resistance, and dimensional stability, make it an ideal candidate for manufacturing processes that require precision and efficiency. As industries continue to evolve and address environmental concerns, the versatility and adaptability of polypropylene will ensure its continued relevance in the ever-changing landscape of modern manufacturing.