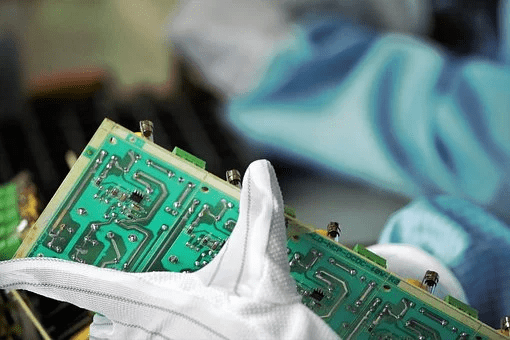

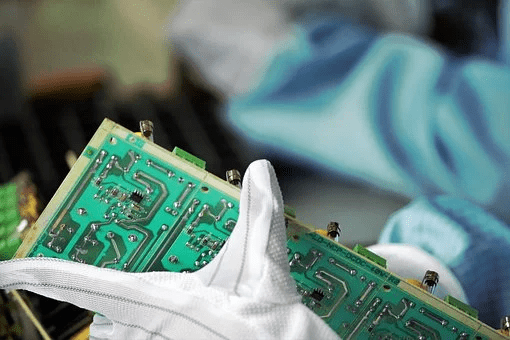

In the electronics manufacturing industry, manufacturing processes are considered to be ?smart? only when they?re cost-effective. A good manufacturing chain is only as good as its weakest link. Returns or warranty-related problems arising from defective products and components can severely damage the business models of electronics manufacturing companies. The good news is that defective products are easily avoidable. The best PCB and electronics assembly manufacturing companies hire inspection experts who don?t allow bad batches of components to leave the manufacturing plant. Who are these PCB inspection experts, and why are they important??

The Importance of PCB Inspection

When you think of ?good? electronics assemblies, what do you expect from these components? A certain level of reliability and long-term performances, right? Well, printed circuit board assemblies are extremely complex items. They feature unique finishes, various components, and of course, the solder that binds all the components together. The slightest of errors or defects in these sub-parts of PCB assemblies can ruin a batch. The IPC has set forward clear inspection guidelines to ensure assembly operators can avoid such errors.

The organization has set up Acceptance Quality Limits (AQLs) that dictate whether PCB batches deserve to be accepted or not. If the sampling and inspection processes reveal that the number of defective components in a batch is more than what the IPC deems ?acceptable,? the entire batch will get rejected, and manufacturers will have to start over again. Without the services of PCB inspection experts, manufacturing companies wouldn?t be able to maintain strict quality standards.

Who Can Apply to be a PCB Inspection Expert?

Professional assembly process engineers, assembly technicians, quality assurance supervisors, soldering professionals, etc., – anyone involved in the electronics manufacturing industry (or hoping to become involved) can apply for a PCB Inspection Course. However, all applicants are required to know the basic inspection requirements and guidelines mentioned in the IPC-A-610 standard before applying for these courses. Familiarity with the IPC guidelines in this standard makes it easier to master processes like –

- X-ray inspection

- Inspecting lead and lead-free components

- BGA inspection

- SMT inspection

- Wire and terminal inspection

- Through-hole inspection

- Visual inspection of electronic assemblies

What is the IPC-A-610 Standard, and Why is it Important in PCB Inspections?

Most electronics manufacturing companies across the globe view the?IPC-A-610 standard?(also known as Acceptability of Electronic Assemblies) as infallible. It?s the most important standard that everyone in the electronics production industry adheres to when defining what products are acceptable or not. The standard separates electronic assemblies into three classes – 1, 2, and 3, with 3 being the highest standard. A Class 3 electronics assembly needs to be built in perfect accordance with the IPC-A-610 Standard as these assemblies are used in critical equipment and tools (aerospace equipment, medical devices, etc.)??

Original Equipment Manufacturers (OEMs) need to understand the basic principles of the IPC-A-610 standard clearly. More importantly, their workforces need to be certified in this standard. That?s because when entire workforces are clear about inspection guidelines and acceptability requirements, avoiding production errors becomes easier. The workers can separate different assemblies based on the three classes and set realistic project goals and deadlines.

IPC-A-610 Certification

Receiving the IPC-A-610 certification is completely different from taking a basic PCB inspection course. But, certified professionals find these courses much easier to complete. After completing their IPC-A-610 certification course, students can expect to –

- Learn the visual representations of the rejection and acceptance criteria for all product classes. Basically, you can determine which soldered connections are acceptable or not just by looking at them.?

- Learn about the different types of component interconnections found in modern-day PCBs.?

- Understand the minimally acceptable conditions for component interconnections and reject batches based on this understanding. The certification essentially makes you an inspection expert capable enough to accept or reject PCB batches.

- Meeting the strict requirements of electronics manufacturing companies becomes much easier.?

- IPC-A-610-certified professionals are recognized across the global electronics manufacturing industry; so, the likelihood of landing the top-paying jobs also increases.?

Applying for PCB Inspection Course

PCB inspection courses were created to improve the skills of all professionals who are tasked with ensuring quality and consistency in electronic assemblies. From production personnel to quality managers ? any industry professional can benefit from receiving a comprehensive understanding of the IPC-A-610 document. Students also get to learn the?IPC-A-600 standard. It?s another vital IPC standard that?s followed by industry professionals when they have to visually verify whether the electronic assemblies meet the minimum acceptance requirements.

IPC inspection courses equip industry professionals with all the information they need to maintain strict quality standards at their workplaces. Professionals who complete these courses along with their IPC certifications learn very quickly. Complex processes like internal or external inspections of printed circuit boards are simplified by the course leaders. So, sign-up for the most student-friendly PCB inspection courses now!

As the editor of the blog, She curate insightful content that sparks curiosity and fosters learning. With a passion for storytelling and a keen eye for detail, she strive to bring diverse perspectives and engaging narratives to readers, ensuring every piece informs, inspires, and enriches.