In the realm of transportation and logistics, innovation is a driving force that shapes the way we move goods efficiently and sustainably. One such innovation that has gained significant attention in recent years is the Curvature Travelling Trolley. This cutting-edge technology promises to revolutionize the way we handle and transport heavy loads in various industries. In this blog post, we’ll explain the purpose, principle, and challenges associated with this curvature travelling trolley.

Curvature Travelling Trolley: Its Purpose

A curvature travelling trolley, often referred to as a curved track trolley, is a specialized piece of equipment used in industries like manufacturing, construction, and transportation. Unlike regular trolleys, which move along straight tracks, this trolley is designed to navigate curved pathways with precision and stability.

The primary purpose of a curvature travelling trolley is to transport heavy loads or equipment smoothly along curved tracks or pathways. This is particularly useful in settings where there’s a need to negotiate corners, bends, or arcs in a controlled manner. The trolley’s design ensures that it maintains a consistent and stable movement, even when navigating tight curves.

These trolleys come in various sizes and configurations to suit different applications, ranging from small-scale manufacturing operations to large-scale construction projects. They play a crucial role in streamlining processes and enhancing efficiency in industries that require precise handling of materials or equipment on curved tracks.

The Working Principle of the Curvature Travelling Trolley

A curvature travelling trolley operates on the principle of centripetal force and friction. When a trolley moves along a curved track, it experiences a change in direction, which requires a force to keep it on the curved path. This force is provided by the friction between the wheels of the trolley and the curved track.

As the trolley moves along the curve, the outer wheels have a longer path to cover compared to the inner wheels. This means they have to travel a greater distance in the same amount of time. To achieve this, the outer wheels must rotate faster. This speed difference creates a relative motion between the wheels and the track.

The friction between the wheels and the track acts as the centripetal force required to keep the trolley moving along the curved path. It prevents the trolley from slipping or skidding off the track. Without this frictional force, the trolley would continue moving in a straight line, causing it to derail.

Curvature Travelling Trolley: Challenges and Limitations

When it comes to the use of curvature travelling trolleys, there are several challenges and limitations that users should be aware of. These factors can impact the efficiency, safety, and overall effectiveness of employing this type of equipment.

Complex Design and Maintenance:

Curvature travelling trolleys tend to have intricate designs, involving specialized components to navigate curved tracks. This complexity can lead to increased maintenance requirements and potentially higher costs associated with upkeep.

Limited Applicability:

These trolleys are specifically designed for curved tracks, which means they may not be suitable for use on straight sections. This can limit their versatility and make them less practical in environments where straight and curved sections are mixed.

Cost Considerations:

Acquiring and installing curvature travelling trolleys can be more expensive compared to standard trolleys designed for straight tracks. The initial investment may be a deterrent for organizations with budget constraints.

Customization Requirements:

Tracks need to be specially designed to accommodate curvature traveling trolleys. This means that existing tracks may need to be modified or new ones constructed, which can involve additional time and costs.

Limited Availability:

Depending on the location and industry, it may be more challenging to find suppliers or manufacturers that offer curvature traveling trolleys. This limited availability could potentially lead to longer lead times for procurement.

Safety Considerations:

Safety is a concern, especially when operating heavy equipment like trolleys. Curvature traveling trolleys may require additional safety measures and protocols to ensure the well-being of operators and other personnel working in the vicinity.

Load Capacity Constraints:

Curvature travelling trolleys may have limitations on the maximum weight they can safely carry. This could restrict their use in scenarios where heavier loads are required.

Environmental Considerations:

Factors such as extreme weather conditions or exposure to corrosive materials could potentially affect the performance and lifespan of curvature travelling trolleys. Specialized materials or protective measures may be necessary.

Risk of Derailment:

Given the specialized nature of curved tracks, there may be a slightly higher risk of derailment compared to trolleys on straight tracks. This emphasizes the importance of regular maintenance and safety checks.

Curvature Travelling Trolley: Look For the Top Brands

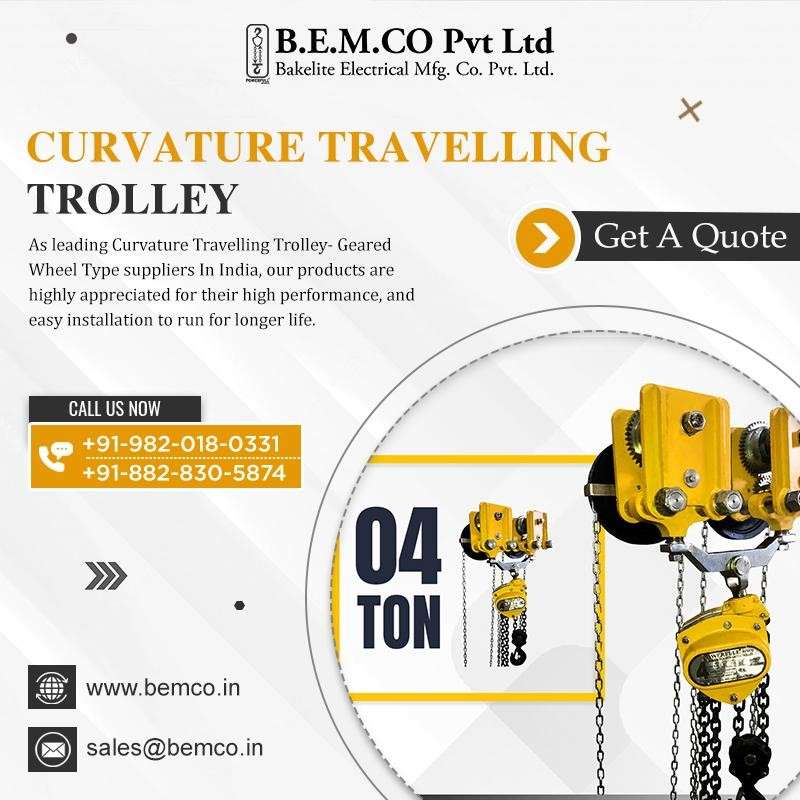

Looking to invest in high-quality curvature travelling trolleys? You can consider buying it from Bemco Pvt. Ltd. – a leading brand that deals in lifting chains and equipment. Being one of the trusted Curvature Travelling Trolley Suppliers in India, we use high-quality raw materials and components to produce these products. For more information about our travelling trolleys, visit our website now.

Curvature Travelling Trolley: Frequently Asked Questions

What are the typical applications of Curvature Travelling Trolleys?

These trolleys are commonly used in manufacturing plants, warehouses, and distribution centers for tasks like transporting heavy loads, assembly line operations, and accessing materials in hard-to-reach places.

Are Curvature Travelling Trolleys customizable?

Yes, many Curvature Travelling Trolley Manufacturers in India offer customization options to suit specific industry requirements. This may include load capacity, track length, and additional features like braking systems or remote control operation.

What are the advantages of using Curvature Travelling Trolleys?

- Efficient use of space: They can navigate tight spaces and corners, making them ideal for facilities with limited maneuvering room.

- Reduced wear and tear: The trolley’s ability to follow curves minimizes friction and wear on both the trolley and the track.

- Improved safety: The design ensures stability and control, reducing the risk of accidents during material handling operations.