When it comes to pumping liquids in various industrial applications, having the right equipment is essential for maximum efficiency and better output. A metallic AODD pump is a reliable type of pump used in various industrial applications to handle a wide range of fluids, including corrosive and abrasive substances.

In this guide, we’ll explore the key benefits of metallic AODD pumps and provide valuable tips to help you select the right one for your specific needs.

Let’s Take A Look At the Overview of Metallic AODD Pump

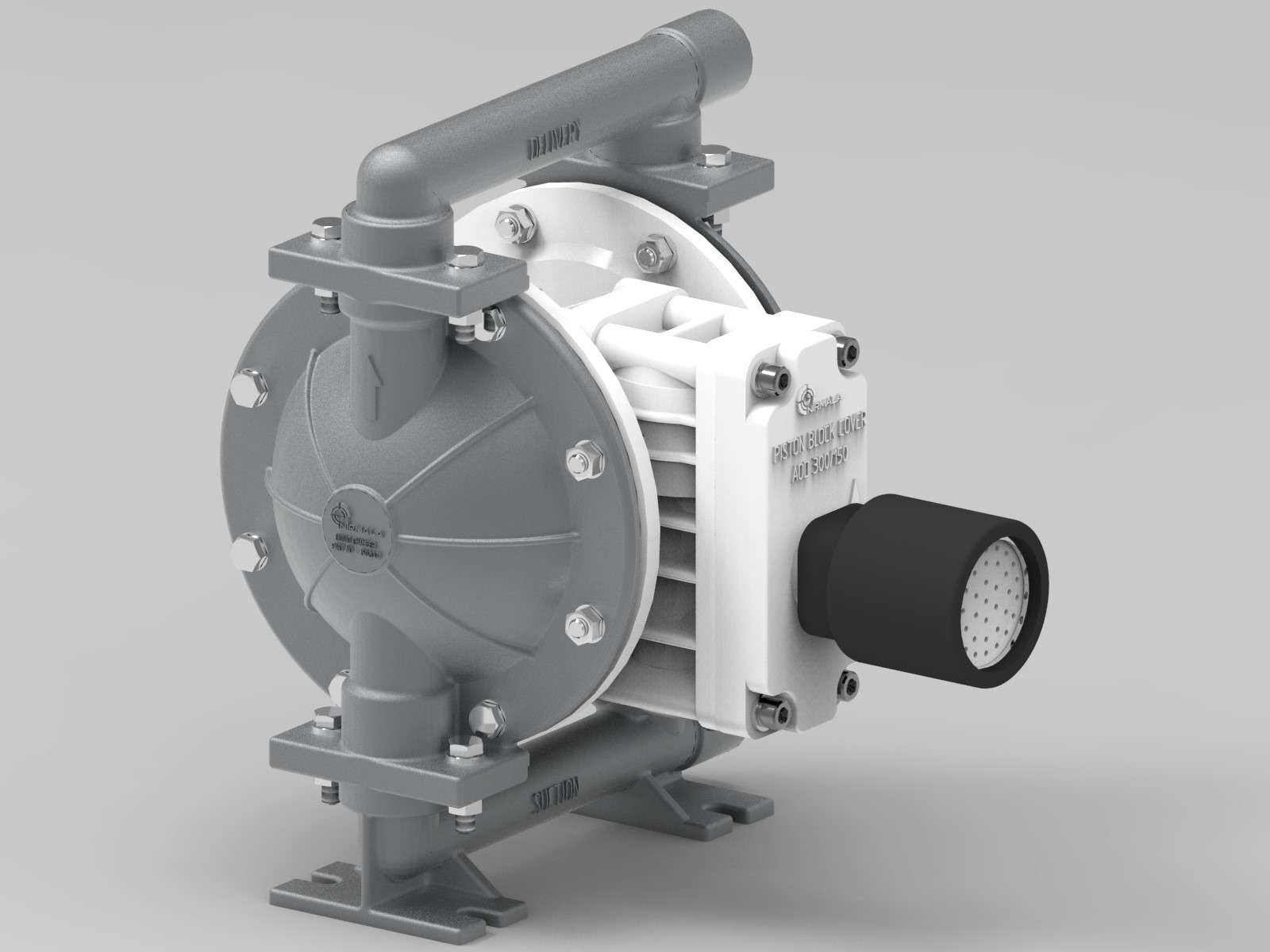

Metallic AODD pumps are a subtype of AODD pumps, which are known for their simplicity and durability. They operate on a pneumatic principle, using compressed air to create reciprocating motion in diaphragms, which in turn draw and expel fluid through the pump.

The primary feature that sets metallic AODD pumps apart is their construction material. These pumps are typically made from various metals, such as stainless steel, aluminum, cast iron, or other alloys, to suit different applications.

Benefits of Metallic Construction for Specific Applications:

Corrosion Resistance: One of the primary advantages of metallic AODD pumps is their ability to resist corrosion. This makes them ideal for industries dealing with corrosive chemicals and acids, such as petrochemical, pharmaceutical, and chemical processing plants.

Durability: Metallic construction enhances the overall durability and longevity of AODD pumps, allowing them to withstand harsh operating conditions and heavy use without significant wear and tear.

Temperature Resistance: Some metallic materials, like stainless steel and specialty alloys, can handle a wide range of temperatures, making them suitable for both hot and cold fluid transfer applications.

Versatility: Metallic AODD pumps are versatile and can be used in various industries, including mining, construction, food and beverage, and paint manufacturing, due to their ability to handle diverse fluid types.

Ease of Maintenance: These pumps are relatively easy to maintain, with fewer components and a simple design, reducing downtime and maintenance costs.

Selecting the right metallic Air-Operated Double Diaphragm (AODD) pump is crucial to ensure optimal performance in your specific application. Consider the following factors before purchasing metallic AODD pumps:

Factors to Consider When Selecting a Metallic AODD Pump:

Fluid Compatibility: Determine the type of fluid you’ll be handling. Consider its chemical composition, viscosity, and whether it’s abrasive or corrosive. Ensure that the materials used in the pump construction are compatible with your fluid.

Flow Rate: Calculate the required flow rate (in gallons per minute or liters per minute) to meet your application’s demand. This should account for both regular operating conditions and potential variations.

Pressure Requirements: Assess the maximum pressure your application requires. Make sure the selected AODD pump can deliver the necessary pressure to move the fluid effectively.

Temperature: Consider the temperature of the fluid you’ll be handling. Ensure that the pump materials and design can withstand the fluid’s temperature range without compromising performance or integrity.

Suction and Discharge Conditions: Evaluate the suction and discharge conditions, including the distance the fluid needs to be moved vertically and horizontally. This information helps determine the pump’s capacity to handle the required head.

Particle Size: If your application involves handling solids or particles, consider the maximum particle size the pump should accommodate. This affects the diaphragm and valve design.

Duty Cycle: Determine the pump’s duty cycle, which refers to how frequently and for how long it will operate continuously. AODD pumps are well-suited for intermittent duty applications.

Air Supply: Ensure you have an adequate and clean compressed air supply, as AODD pumps rely on compressed air to operate.

Sizing Calculations and Guidelines:

Once you have a clear understanding of your application’s requirements, you can proceed with sizing your metallic AODD pump. Here’s a simplified guideline:

- Calculate the required flow rate in GPM (gallons per minute) or LPM (liters per minute).

- Determine the maximum discharge pressure required in PSI (pounds per square inch) or bar.

- Refer to the performance curve for the selected AODD pump offered by reputable Metallic AODD Pump Suppliers in India. This curve provides information on flow rate and pressure capability for various pump sizes.

- Choose a pump size that meets or exceeds your calculated flow rate and pressure requirements while considering factors like fluid viscosity and temperature.

- Keep in mind that AODD pumps can be oversized for a margin of safety. However, excessive oversizing can lead to inefficient operation and higher energy consumption.

Matching the Pump to Your Specific Application Requirements:

Once you’ve selected the appropriate metallic AODD pump based on the factors above and sizing calculations, it’s essential to ensure it meets your application’s unique demands. This involves:

Installation: Follow the guidelines of top Metallic AODD Pump Manufacturers in India for proper installation and ensure all connections, hoses, and fittings are secure and leak-free.

Monitoring: Implement a monitoring system to regularly check the pump’s performance, diaphragm condition, and air supply. This helps identify issues early and prevent downtime.

Maintenance: Adhere to recommended maintenance schedules, which may include diaphragm replacement, valve maintenance, and cleaning to prolong the pump’s lifespan and maintain efficiency.

By carefully considering these factors, performing accurate sizing calculations, and ensuring proper installation and maintenance, you can confidently match a metallic AODD pump to your specific application requirements for reliable and efficient fluid handling.

Conclusion

Metallic AODD pumps offer a wide range of benefits, including durability and ease of maintenance. By following the selection tips outlined in this guide, you can make an informed choice and ensure that your metallic AODD pump meets the specific needs of your application.

With a huge experience in this sector, Nirmala Pumps & Equipment has earned a reputation as the top manufacturer of metallic AODD pumps. Learn more about their range of AODD pumps by visiting their website.

Frequently Asked Questions

What are the advantages of using metallic AODD pumps over non-metallic ones?

Metallic AODD pumps offer enhanced durability and corrosion resistance, making them suitable for more demanding applications. They are ideal for pumping corrosive fluids and can withstand harsh operating conditions.

What materials are typically used in metallic AODD pumps?

Common materials include stainless steel, aluminum, and various alloys. The choice of material depends on the compatibility with the pumped fluid and the required durability.

Are metallic AODD pumps energy-efficient?

AODD pumps are not the most energy-efficient pump option, but they are known for their reliability and versatility. Their energy consumption depends on factors like air pressure and flow rate. Some models have energy-saving features.