The COVID-19 virus and the subsequent lockdowns seriously impacted the electronics manufacturing industry. Restrictive containment measures prevented industry professionals from visiting their factories. Social distancing rules triggered a new wave of remote workers. The complete closure of commercial activities across the globe created quite a few operational challenges for all electronics manufacturing industry members.

In 2021, several electronics manufacturing companies are hoping to rearrange their daily operations and recover from the massive financial hits that the industry took in 2020. The increasing demand for electronic products across the world suggests that these recovery attempts will be successful. The global electronics market is projected to be valued at?$3077.02 billion?by the end of 2021, a sharp increase from the 2020 valuation of $2831.25 billion (at a Compound Annual Growth Rate of 8.7%).

So, everything in the electronic manufacturing industry will be perfect in 2021, right? No! Electronic manufacturing firms face countless challenges in the next three years as they compete to discover new techniques and innovations. Some pressing issues that key players in the electronics manufacturing industry will face include –

- Fighting Regulations:?Electronics manufacturing processes generate?40 million tons?of electronic waste globally every year. As demand for new electronic components keeps rising, the onus is on the key players in the electronics manufacturing industry to cutdown their e-waste production levels and train their employees to follow the latest e-waste regulations.

- Demand for Better Quality:?Every year, millions of counterfeit electronic components are created, used, and re-circulated worldwide. These substandard parts damage the qualities of electronic products. So, authorized manufacturers are looking to find new ways to distinguish their components from fake parts. The soldering and electronics assembly professionals working for these manufacturing businesses will have to go the extra mile and offer better services.

- Following Quality Standards: Despite the fact that the number of electronics manufacturing companies has steadily increased over the past fifty years, all manufacturers use the same quality standards set by the IPC (Association Connecting Electronics Industries). The global electronics manufacturing industry acknowledges the standards and strict quality control measures created by the IPC. But, not all soldering and electronics assembly professionals are trained to comply with these specific standards.

The solution to all three of these challenges is creating workforces full of trained and IPC-certified professionals. Soldering specialists and electronics assembly professionals who undergo these comprehensive training programs, on-site assessments, and certification procedures are able to provide higher-quality outputs.

Be it complying with the latest regulations from the European Environment Agency (EEA) or creating highly customized electrical components – soldering and electronics assembly professionals who receive proper training and certifications can ensure that all IPC standards are met while they’re working at their employers’ manufacturing plants.

IPC-certified professionals can also consistently evaluate the components they manufacture and determine whether they’re “acceptable” or not as per the latest IPC standards.

Challenges of Training During the Pandemic

Due to the restrictive containment measures, several soldering and electronics assembly professionals could not complete their training and certification programs on time in the early months of 2020.

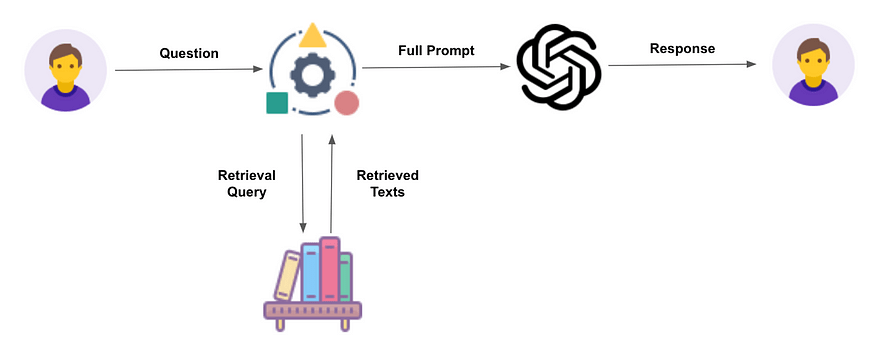

In response to these difficulties, leading IPC-certified training course providers are now offering?online Soldering Training. These training centers collaborate with the IPC and take all necessary preparations to provide online IPC training courses.

In July 2016, the IPC launched an online learning platform called ‘IPC Edge.’ This platform provided trainees with the resources they needed to develop their skills and thrive as members of the electronics industry. The new online training programs are similar to IPC Edge. All training programs are available to students 24X7.

Students don’t need to risk their health by traveling to IPC-certified training centers. They only need internet-connected computers, laptops, or tablets to access webinars, white papers, and instructional videos on whatever IPC standards they’re trying to master. These online courses are identical to real-life courses in terms of the education and skills students can gain from them. Participating in these online courses is very simple –

- Purchase access to whichever courses you want.

- Gain access to course materials, webinars, white papers, etc.

- Complete the coursework and take the exams from your home.

- Students who pass the certification exams can print their certificates of completion from the training institute’s official website.

Why Take Online IPC Training??

Despite the lockdowns, the IPC hasn’t stopped revising its standards. In 2020, the globally acclaimed trade association released more than 20 revisions to previous standards. For instance –

- The IPC/WHMA-A-620 standard got its ‘D’ revision in January 2020. This 420-page long revised document is yet to be adopted by professionals in the electronics manufacturing industry.

- In September 2020, another very important IPC standard called the ‘IPC-A-610 Standard’ was revised. The “H” revision is expected to be followed by all professionals in the global electronics manufacturing industry.

Online training enables soldering and electronics assembly professionals to stay updated about these revisions. The safety of the students is every IPC-certified instructor’s priority. So, professionals who want to be certified or re-certified during this crisis must take online IPC certification courses and prepare for the challenging years ahead.