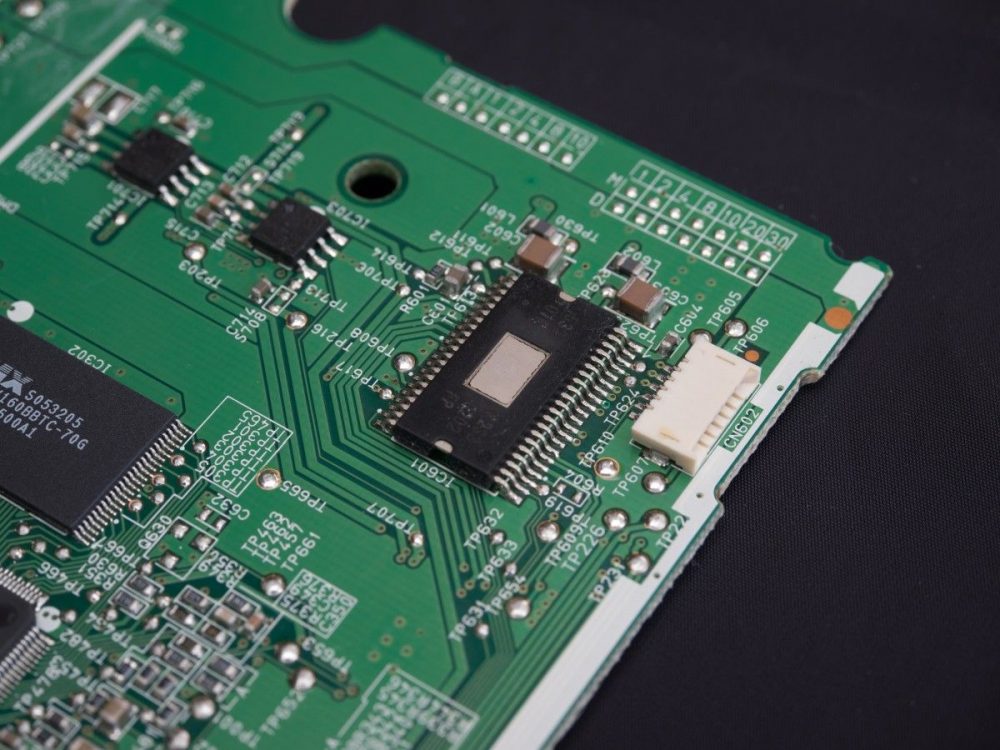

This article updates your knowledge about printed circuit board prototyping as well as printed circuit board assembly. Let?s start.

By all probability, you possibly know regarding the significance & requirement for printed circuit boards, also called PCBs. The development of PCBs is greatly dependent upon by a set of needs, which are typically provided to the manufacturer by the customer. Not to mention, printed circuit boards are now a part of every electronic gadget and machine that you can possibly see with your naked eyes. The process of assembling electronic elements over the board is known as printed circuit board assembly.

The needs are determined upon a lot of factors, majorly based over the functions & features of the finished product. A printed circuit board prototype is developed to meet up these needs, which could moreover assist mass manufacturing, as needed by the customer.

Acquiring printed circuit board prototypes

Prior to manufacturing of PCBs or printed circuit board assembly could initiate, the pertinent customer get in touch with one of the skilled manufacturers in the industry with their business needs. At this point of time, the priority is to make the prototype ready. Because of this, a few manufacturers have a competitive edge over others, and they could make the prototype ready in a shorter duration of time.

A few PCBS call for more time, particularly as the needs are comprehensive. Simultaneously, some boards could be developed with only 2-3 layers; on the contrary some prototypes might require as much as 32 or even more. Further, it is important to concentrate over the size & function of the prototype, as it ought to fit the design & box needs. Each layer as well as copper trace is greatly significant & should be developed under huge tolerance. Further, the testing is conducted at more than one level to find out whether all the functions and needs have been served up.

Facts to note?

Developing the PCB prototype is a factor which majorly decides the final usage of printed circuit boards, and as a result, the design fabrication procedure must be as precise as probable.

The associated manufacturer has to have a team which could maintain up the reliability of the printed circuit board prototype meanwhile tracking the customer needs. To put it general, PCBs are tested for a plethora of times, and it calls for more than some independent tests to make sure that all functions are working as per the requirement. The concerned fabricator would note down these results & would address all the rational concerns in a familiar manner.

Discovering a manufacturer

When you are discussing printed circuit board assembly and prototype, majorly customers do not wish to know what happens in the manufacturing method, as they all need is a functional printed circuit board prototype which could be employed for production in bulk. If that is the thing with you, go for firms which are reputed in the industry and are well recognized.??

They have to be capable to give help on your wants & have to be well known with regards to printed circuit board prototyping. They must also have the needed investments as well as infra to aid full ranging production, and their team must be available & frank to fresh ideas & possible difficulties.

Apparently, you have to get a deadline for the associated PCB prototype, & the associated company should as well give a comprehensive review of their manufacturing procedure with estimation.

Demand an inclusive estimation, as the prices are subject to change. For deeper understanding of their work, ask for their references. You can know about the company by going through the reviews provided by their present and past clients of different industries.