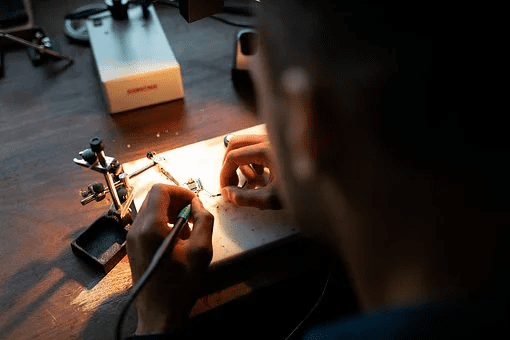

?J-standard soldering? is a type of soldering that follows all the parameters set by the IPC document called J-STD-001C. This standard is vital for all soldering professionals, so much so that a whole category of soldering is dedicated to it. Several electronics institutes also teach soldering that conforms with the IPC J-STD-001C standard?s parameters. The parameters aim to clarify methods and verification criteria for manufacturing high-quality soldered assemblies and interconnections.

What is the J-Standard?

IPC or the Association Connecting Electronics Industries (commonly known as the Institute of Printed Circuits) was founded in 1957. In 1958, the association released its first guidebook called, ?How to Design and Specify Printed Circuits??. Since then, IPC has released several standards that set the playing field for all soldering professionals. These standards are updated every year as per the trends and demands of the soldering, electronics assembly, and electronics manufacturing industries.

The IPC J-STD-001 or simply the ?J-standard? is one of the industry?s most widely revered and used standards. The document is entitled ?Requirements for Soldered Electrical and Electronic Assemblies? and is the perfect source of information about process control in assembly processes. The document covers topics like –

- What equipment types are allowed/not allowed to be used in soldering processes.

- What materials are allowed/not allowed to be used in soldering processes

- The standard sets guidelines for work facility conditions, such as lighting arrangements, required temperatures, humidity levels, etc.

- General requirements like the health and safety of assembly line operators are also discussed.

- Standards for surface mounting, reworking, and repair of components.

- Instructions for through-hole mounting processes.

- Guidelines on the wire and terminal connections.

- Components and equipment requirements.

- General soldering and assembly terms and definitions.

- Mandatory personnel proficiency levels.

Apart from these general guidelines on soldering and assembly processes, the IPC-J-STD-001 also contains highly specific topics that users can?t find in any other IPC standard. For instance, the chapter entitled ?Cleaning Process Requirements? specifies the guidelines soldering professionals need to follow while carrying out cleaning processes like ultrasonic cleaning. This chapter is dedicated to all acceptable cleanliness test methods for soldering professionals.

There are also specific chapters on Product Assurance and PCB Requirements. Soldering professionals can learn about process control requirements, statistical process control, and other product assurance techniques from this document. The PCB requirements chapter addresses topics like haloing, de-panelization, delamination, etc.

Why Following the J-Standard is So Hard?

There are two reasons why following the IPC-J-STD-001 is very difficult for soldering professionals –

- Ever-Evolving

IPC realized that the introduction of component configurations or material-related guidelines prompt rapid industrial changes. New technologies address these changes. As a result, product demands increase, which in turn makes it impossible for the IPC to avoid additional changes to the IPC-J-STD-001 specifications and training documentations. Hence, the IPC now updates the IPC-J-STD-001 (and other standards) every three years instead of five years.

This significant change in schedule impacts the professionals using the standards. They have to physically review the updated documents to know about the latest IPC technical standards. In September 2020, the IPC launched the latest ?H? revision publication of the J-STD-001. Hence, the most important standard for soldering processes needed to be re-read and re-understood once again by professionals from across the world.

- Complexities in the Document

The J-STD-001 or the ?J standard? was drafted in two different segments. The first section covers general topics like material selection, equipment guidelines, etc. The second section details different solder connection styles require while working with different types of electronics product components. There are four sub-sections of the second part – inspection of the solder joints, wires, terminals, surface mount technology (SMT), and plated through-hole technology. Every section of the document contains the theories behind these processes and some workmanship demonstrations (images, directions, instructions, etc.).

Naturally, it?s hard for soldering professionals to keep all of this information in their minds while working in intense facilities. Plus, it can be extremely challenging always to remember which revision was mentioned in which update of the J-standard.

How to Master the J-STD-001 Standard

Here are two ways soldering professionals can master the J-STD-001 standard.

- Revise: Revise the previous updates to the document. Currently, there are eight revised versions of the J-STD-001. Before reading the latest ?H? update, soldering professionals are advised to re-read the past updates. Revise all important J Standard soldering materials as frequently as possible.

- IPC Certification: The best way to learn all the fine points of the J-STD-001 standard (and its updates) is by receiving IPC certification training. The best J-STD-001 certification courses teach soldering professionals via written exams (to ensure they know the theories), hands-on soldering projects, demonstrations of SMT technologies, practical soldering jobs on wire and terminals, and plenty more.

In workmanship training courses, trainees get to try out the methods and theories prescribed by the J-standard!??