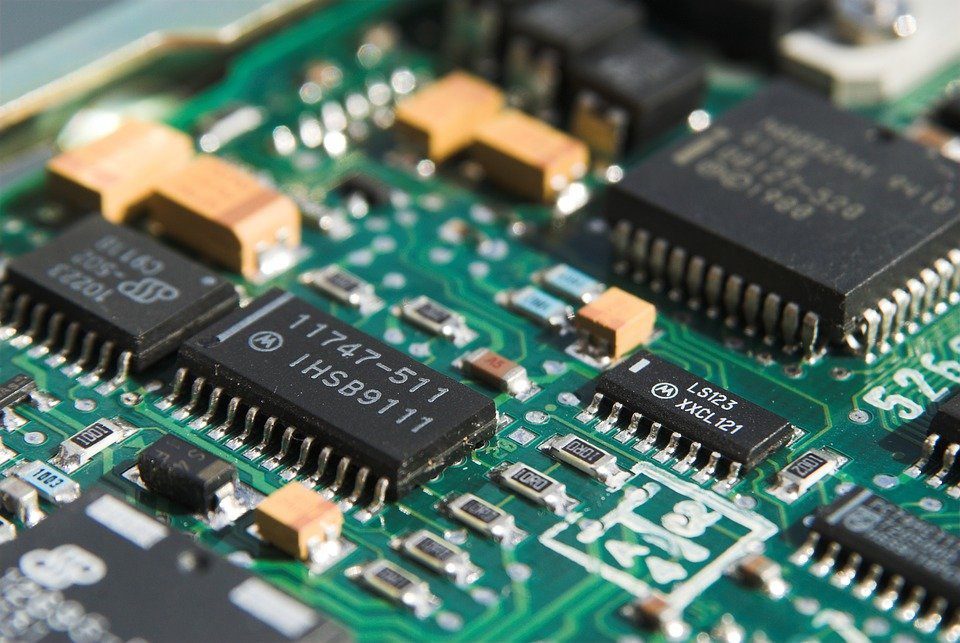

The electronic devices that we use today have cores that is mostly formed by Printed Circuit Boards. Everything from mobile phones to cars has electronic components and at the core of these are the printed circuit boards. Such electronic components in UK can be found in online stores or local shops. The PCBs are composed of tiny and fine components which are designed very carefully according to the desired requirements and meet the desired outcomes.

Therefore PCB assembly is a lengthy process yet simple. But we should not be fooled by the simplicity of the process. The smallest of details need a lot of attention because the smallest of mistakes can cause drastic errors. That is why it is necessary to pay attention in the steps of assembly process.

PCB Assembly Process Steps

Solder Paste Stenciling

The initial step of PCB get together is applying a patch glue to the board. This cycle resembles screen-printing a shirt, besides rather than a veil, a slender, tempered steel stencil is put over the PCB. This permits constructing agents to apply solder glue just to specific pieces of the eventual PCB. These parts are the place where segments will sit in the completed PCB.

The weld glue itself is a grayish substance comprising of small bundles of metal, otherwise called solder. The organization of these minuscule metal balls is 96.5% tin, 3% silver and 0.5% copper. The weld glue blends bind in with a motion, which is a compound planned assistance the solder liquefy and attach to a surface. Solder glue shows up as a dim glue and should be applied to the board at precisely the correct spots and in accurately the perfect sums.

In an expert PCBA line, a mechanical apparatus holds the PCB and bind stencil set up. An instrument at that point places bind glue on the planned regions in exact sums. The machine at that point spreads the glue across the stencil, applying it uniformly to each open territory. In the wake of eliminating the stencil, the bind glue stays in the expected areas.

Pick and Place

By using an automated system we can manually and mechanically mount the components which is a pick and place activity. Component mounting is performed manually in through-hole PCB assembly. Whereas it is done by an automated machine in Surface-mount PCB assembly. Both processes work fine but automated process provides quick and error free results.

Soldering

To join together the components on PCB soldering is performed. The wave soldering is performed in through-hole assembly. In this process first a PCB that is mounted with Electronic Components in UK is passed through a hot wave solder liquid. What happens is that solder balls melt and when it passes through room temperature it solidifies again. Whereas reflow soldering is performed in surface mount PCB assembly. In this process the PCB is passed through a furnace at high temperature which then melts and on cooling settles on the PCB components.

Inspection

Inspection is an important procedure to make sure that the device is functioning properly therefore quality testing should be given high amount of importance. Inspection can be performed in three ways:

Manual Inspection

Manual inspection is performed in person but this can only be possible for a small batch PCBs. The soldered connections are checked carefully.

Automatic Optical Inspection

Automatic inspection is performed through an AOI machine in which the PCBs are checked through high resolution cameras. Only single and double layered PCBs can be inspected with it otherwise it?s not suitable for multi layered PCBs.

X-ray Inspection

X-ray inspection is more suitable for multi layered printed circuit boards. Such designs of PCBs are complex and cannot be inspected optically.

Post Assembly Inspection and Testing

Once the assembly process is completed the PCBs are tested again for their functionality to ensure all the electronic components are mounted properly and it performs the desired functions. Such high quality electronic components in UK can be found on online stores. Tests like Micro-sectioning test, contamination test, Solderibility test, are performed to conclude the process.